Lionsol ONE Erp India - Snapshot of Your Business

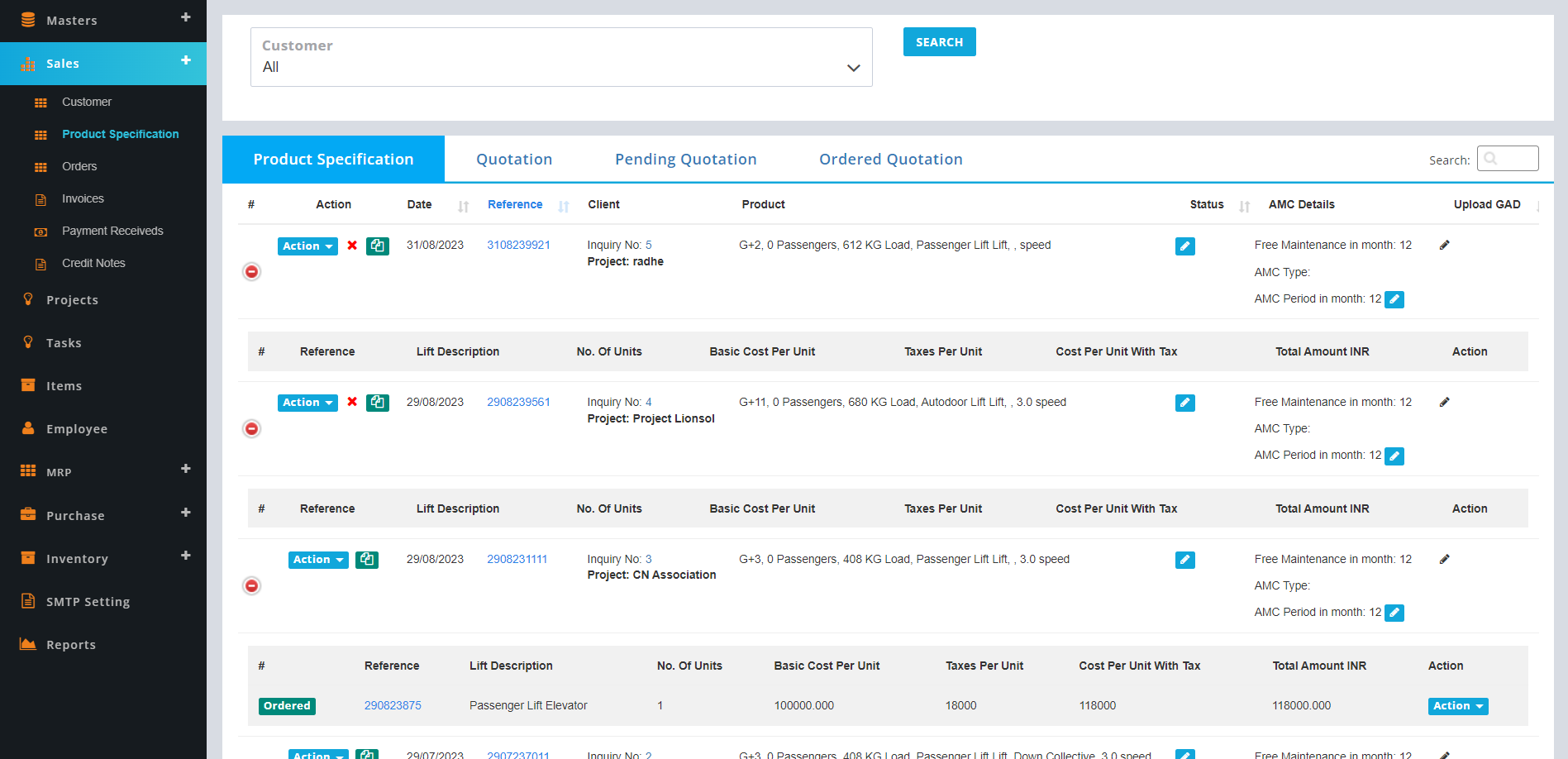

With your Customer and Inventory data organized on the cloud, you can track Price Cut off Production, create and send quotation And know how your business Inquiry is doing at any time. What's more, easy to use and you need not be an expert to use Liosnol One ERP.

For manufacturers, choosing the right ERP (Enterprise Resource Planning) software is crucial to efficiently manage their production processes, supply chain, inventory, and other aspects of their business. Here are some key features and considerations when selecting ERP software for manufacturing:

1. **Production Planning and Scheduling:** Look for ERP systems that offer robust production planning and scheduling tools. This helps optimize production processes, allocate resources efficiently, and reduce lead times.

2. **Inventory Management:** Effective inventory management is critical for manufacturers to minimize carrying costs and prevent stockouts. The ERP should offer features for real-time inventory tracking, demand forecasting, and reorder point optimization.

3. **Quality Control:** Ensure the ERP includes quality control and assurance modules to maintain product quality standards and compliance with industry regulations.

4. **Supply Chain Management:** A strong supply chain module helps in managing supplier relationships, tracking shipments, and ensuring timely delivery of materials.

5. **Bill of Materials (BOM):** Manufacturing ERPs should support complex BOMs, allowing you to define the structure of your products and manage changes efficiently.

6. **Shop Floor Control:** Features for real-time monitoring of production activities on the shop floor can improve visibility and control over manufacturing processes.

7. **Costing and Financials:** Comprehensive financial management capabilities are important for tracking costs, managing budgets, and analyzing profitability.

8. **Integration:** Ensure that the ERP system can integrate seamlessly with other software and hardware used in your manufacturing environment, such as CAD/CAM systems or IoT devices.

9. **Scalability:** Consider your future growth plans. The ERP should be able to scale with your business as it expands.

10. **User-Friendly Interface:** A user-friendly interface is essential for easy adoption by your staff. Training requirements should be manageable.

11. **Compliance:** Depending on your industry, you may have specific compliance requirements (e.g., FDA regulations for pharmaceuticals). Ensure the ERP can help you meet these.

12. **Support and Maintenance:** Look into the support and maintenance services offered by the ERP vendor to ensure you have assistance when needed.

Popular ERP solutions for manufacturing include One ERP for Finance and Operations, and Epicor ERP, among others. Evaluating your specific manufacturing processes and needs will help you choose the ERP software that aligns best with your business goals. Additionally, consider consulting with ERP experts or seeking recommendations from industry peers for valuable insights.One ERP Production is a web version that consists of flawless processing, ease of access, rapid response with secure service management for Service & Manufacturing companies.